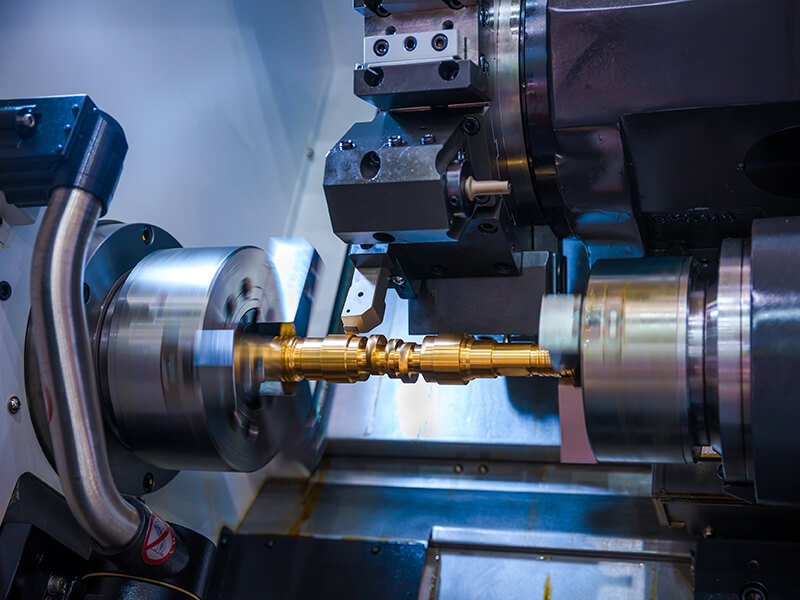

Custom CNC Milling Services

- 3–Axis, 4-Axis, and 5-Axis CNC Milling

- From Single Prototype to 100,000+ Units

- Lead Time as fast as 1 day

CNC Milling Serivce for Custom Parts

3-axis CNC Milling

Most cost-effective option for quality parts. For straightforward designs, you get top precision without the extra cost.

4-axis CNC Milling

Got features on the sides? This machine hits them in one setup, which means higher accuracy and faster delivery for your parts.

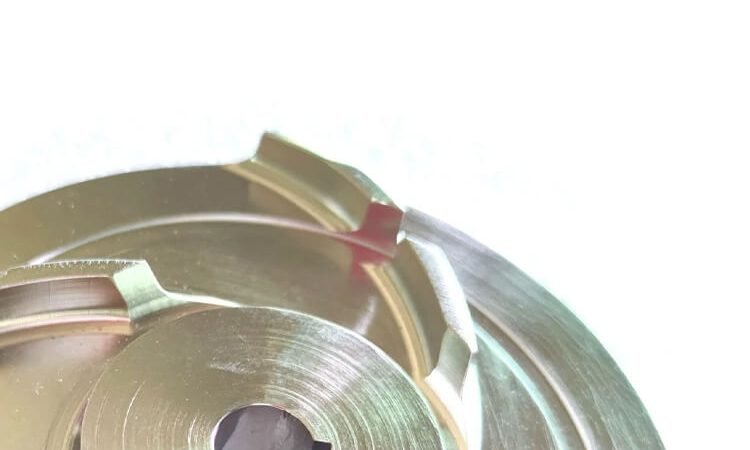

5-axis CNC Milling

Bring on your most complex designs. This is how we create those "impossible" parts with curved surfaces and tricky angles, perfectly.

CNC Milling Solutions

Rapid Prototyping

- Instant Design Feedback

- Swift Concept Validation

Low and High-Volume Production

- Scalable Production Efficiency

- Consistent Quality Assurance

CNC Milling Materials

Aluminum

Aluminum offers high strength-to-weight ratio, corrosion resistance, and excellent thermal/electrical conductivity, making it ideal for aerospace, automotive, and precision CNC machining. Its machinability and weldability ensure fast, cost-efficient production without sacrificing performance.

Alloys:

Aluminium 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu Aluminium 6082-T651 | 3.2315 | 64430 | AlSi1MgMn Aluminium 6060 | 3.3206 | AlMgSi Aluminium 5052 | EN AW-5052 | 3.3523 | AlMg2,5 Aluminium 2017 | 3.1325 | 24530 | AlCu4MgSi

Available Finish:

As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Brass

Brass delivers an unbeatable combo of machinability (20% faster than steel), corrosion resistance, and antimicrobial properties—making it the go-to for precision valves, marine fittings, and medical instruments. This golden alloy balances strength with ductility, conducts heat/ electricity like a champion, and polishes to jewelry-grade brilliance for decorative hardware and audiophile components.

Alloys:

H59, H62, C260, C360

Available Finish:

As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish

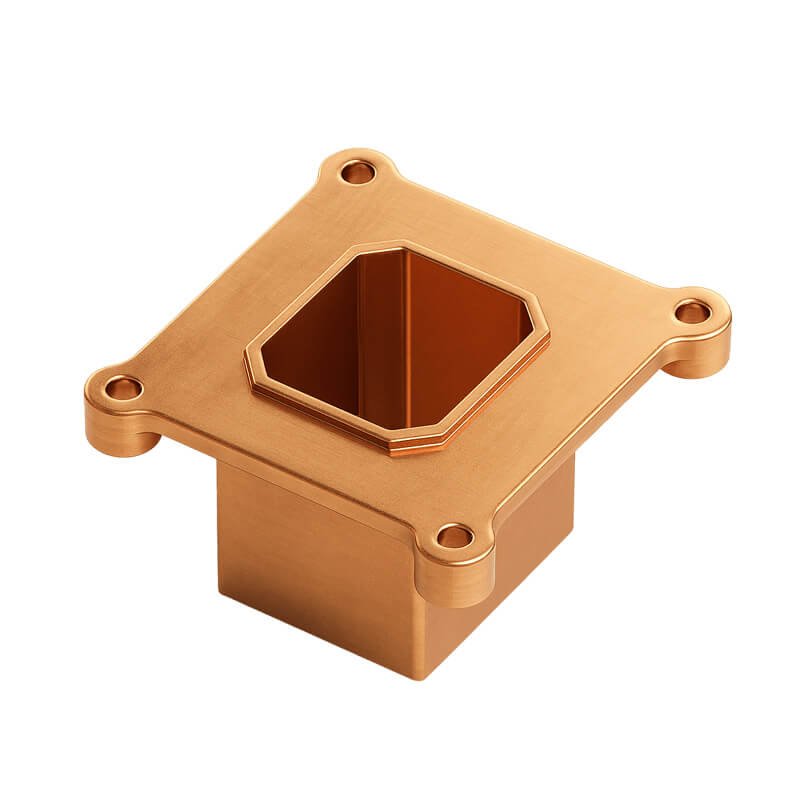

Copper

Copper delivers superior electrical & thermal conductivity with excellent corrosion resistance, perfect for electrical components, heat exchangers, and precision CNC machined parts. Its high ductility and machinability allow tight tolerances while maintaining durability under stress.

Alloys:

C11000, C10100, C10200

Available Finish:

As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish

Bronze

Bronze combines high strength, wear resistance, and low friction with natural corrosion protection, making it ideal for bearings, marine hardware, and precision CNC components. Its machinability and fatigue resistance ensure long-lasting performance in demanding mechanical and chemical environments.

Alloys:

C64200, C93200

Available Finish:

As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish

Steel

Steel offers exceptional strength, durability, and impact resistance while maintaining reliable machinability for tight-tolerance components. Its versatility in heat treatment and corrosion-resistant alloys makes it ideal for automotive, aerospace, industrial machinery, and structural applications.

Alloys:

Structured Steel, Mold Steel, Alloy Steel, Tool Steel, Bearing Steel, Carbon Steel

Available Finish:

As machined, Electroplating, Passivation, Powder coating

Stainless Steel

Stainless steel delivers superior strength, corrosion resistance, and heat tolerance with excellent machinability for precision parts. Its hygienic and oxidation-resistant properties make it essential for medical, food processing, marine, and chemical industries.

Alloys:

Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

Available Finish:

As machined, Electroplating, Passivation, Powder coating

Magnesium

Magnesium provides exceptional lightweight strength, high stiffness-to-weight ratio, and excellent thermal conductivity while maintaining good machinability. Its natural EMI shielding and biodegradability make it perfect for aerospace, automotive, electronics, and medical implants.

Alloys:

AZ31B, AZ91D, AZ61B, ZK61M, MB15-RE

Available Finish:

As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis

Titanium

Titanium offers unmatched strength-to-weight ratio, extreme corrosion resistance, and high-temperature stability while remaining highly machinable for precision components. Its biocompatibility and durability make it ideal for aerospace, medical implants, marine, and high-performance automotive applications.

Alloys:

Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

Available Finish:

As machined, Polishing, Sand Blasting, Tumbling, Electropolish, Alodine, Anodizing, Electroless nickel, Painting, Powder coating, Brushed finish

ABS

ABS combines high impact resistance, toughness, and good thermal stability with excellent machinability and surface finish potential. Its chemical resistance and affordability make it ideal for automotive parts, consumer electronics, prototypes, and industrial housings.

Subtypes:

ABS Beige(Natural), ABS Blac, ABS Black Antistati, ABS Milky Whit, ABS+PC Black, ABS+PC White

Available Finish:

As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating, Electrophoresis

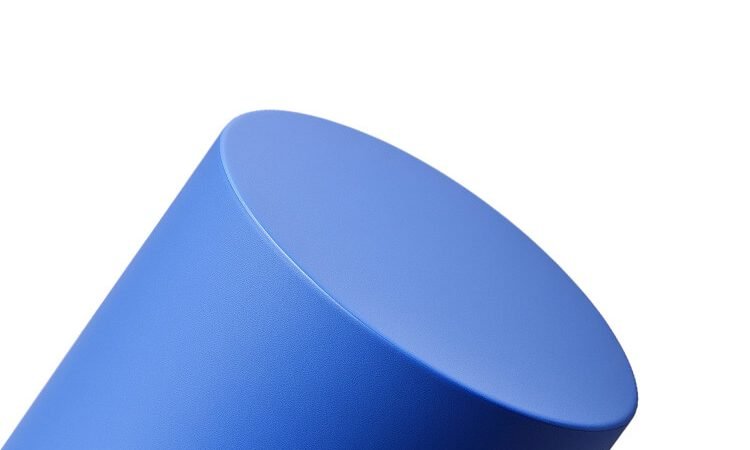

PC

PC (Polycarbonate) offers exceptional impact resistance (250x stronger than glass) while maintaining optical clarity, lightweight versatility, and easy machinability—perfect for medical devices, safety gear, and automotive lenses. With high thermal stability and resistance to acids/alcohols, PC thrives in environments demanding transparency and rugged durability, from electronics to bulletproof glazing.

Subtypes:

PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black

Available Finish:

As machined, Sand blasting, Tumbling, Painting, Brushed Finish

HDPE

HDPE offers high strength-to-density ratio, excellent impact resistance, and moisture-proof stability while being easily machined, welded, or thermoformed. Its chemical resistance and low-cost durability make it ideal for fluid storage tanks, corrosion-resistant piping, food-grade containers, and outdoor industrial components.

Subtypes:

HDPE Black, HDPE White

Available Finish:

As machined, Sand blasting, Tumbling, Painting, Powder coating, Teflon coating

PTFE

PTFE defies friction with the lowest coefficient of any solid (0.05-0.1), laughs at 260°C molten aluminum while remaining chemically inert to every acid—including aqua regia—yet mills into self-lubricating seals and non-stick labware that outperform stainless steel in semiconductor wafer carriers and FDA-compliant food processing.

Subtypes:

Teflon (PTFE) Black, Teflon (PTFE) White

Available Finish:

As machined, Sand blasting, Powder coating, Brushed finish

POM

POM (Delrin®) brings surgical precision to CNC machining—delivering stiffness rivaling aluminum, near-zero moisture absorption, and self-lubricating smoothness that outperforms metals in gears, rollers, and high-wear components.

Subtypes:

Dark brown (coffee) POM 100AF, POM Black, POM Blue, POM White

Available Finish:

As machined, Sand blasting, Tumbling, Painting

PE

PE (Polyethylene) combines lightweight flexibility with high impact strength, excellent moisture resistance, and effortless machinability—ideal for fluid containers, chemical tanks, and medical packaging. Its chemical inertness (resists acids, alkalis, and solvents) and low-cost durability make it the workhorse of consumer goods, industrial liners, and food-safe applications.

Subtypes:

HDPE, UHMW-PE, LDPE

Available Finish:

As machined, Sand blasting, Tumbling, Painting, Powder coating

PMMA

PMMA (Acrylic) shines with optical clarity (92% light transmission), glass-like rigidity yet half the weight, UV/weather resistance, and effortless thermoforming—a staple for lenses, displays, and outdoor signage. Though brittle, its scratch resistance and biocompatibility make it ideal for medical devices, LED optics, and architectural glazing where aesthetics meet endurance.

Subtypes:

PMMA Black, PMMA Transparent, PMMA White

Available Finish:

As machined, Sand blasting, Tumbling, Painting

PEEK

PEEK (Polyetheretherketone) boasts aerospace-grade strength—retaining stiffness at 250°C, resisting hydrolysis and aggressive chemicals, while machining like high-performance metal—perfect for oil & gas valves, spinal implants, and semiconductor parts. This “liquid metal” of plastics delivers unmatched wear resistance, sterilization stability, and weight savings for extreme environments from deep-sea robotics to jet engines.

Subtypes:

PEEK Beige(Natural), PEEK Black

Available Finish:

As machined, Sand blasting, Tumbling, Painting, Powder coating

CNC Milling Surface Finishes

As Machined

Sand Blasting

Polishing

Anodizing

Electropolishing

Painting

Power Coating

Zinc Plating

Black Oxidize

Chrome Plating

Nickel Plating

Brushing

Tolerances for CNC Milling

| Parameter | Standard Tolerance | Precision Tolerance | Ultra-Precision Tolerance |

|---|---|---|---|

| Linear Dimension | ±0.1 mm | ±0.01 mm | ±0.005 mm |

| Hole Dimension | ±0.05 mm | ±0.01 mm | ±0.005 mm |

| Shaft Dimension | ±0.05 mm | ±0.01 mm | ±0.005 mm |

| Flatness | 0.1 mm/100 mm | 0.02 mm/100 mm | 0.01 mm/100 mm |

| Surface Roughness | Ra 1.6 μm | Ra 0.8 μm | |

| Angular Tolerance | ±0.5 degrees | ±0.1 degrees | ±0.05 degrees |

| Position Tolerance | ±0.1 mm | ±0.02 mm | ±0.01 mm |

| Parallelism | 0.1 mm/100 mm | 0.02 mm/100 mm | 0.01 mm/100 mm |

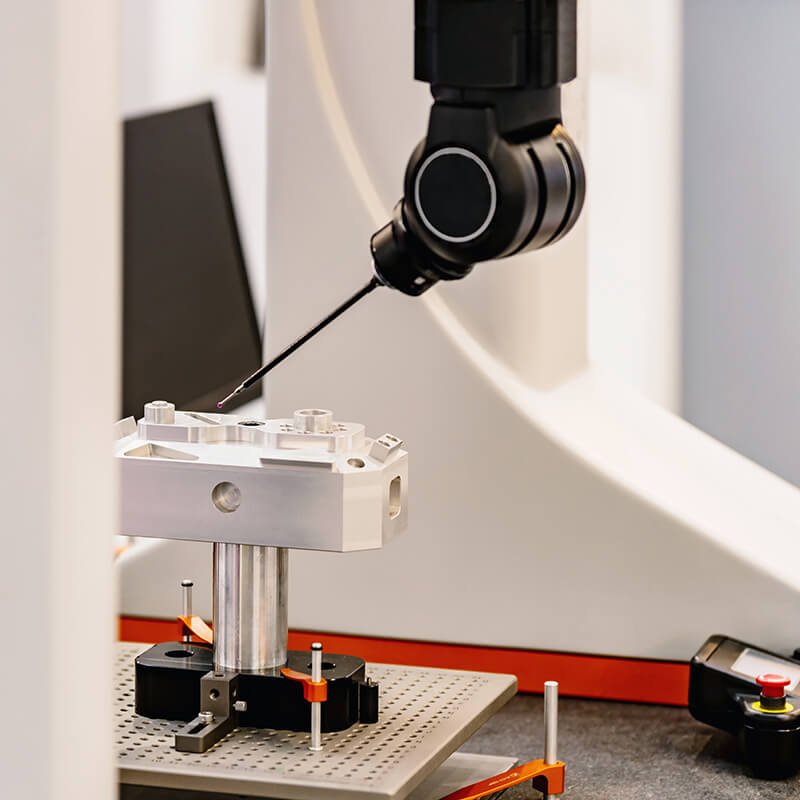

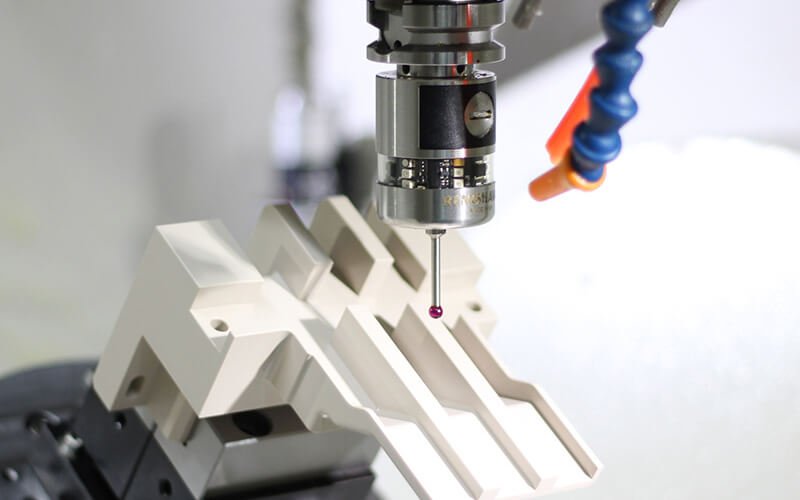

High-Quality Every Time

- 20+ advanced inspection equipment

- 10+ quality control professionals

- Continuous improvement with PDCA methodology

- ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949

Design Guidelines of CNC Milling

| Title | Description |

|---|---|

| Internal Radii | Ensure at least 1/3 of cavity depth; larger radii preferred for strength and durability. |

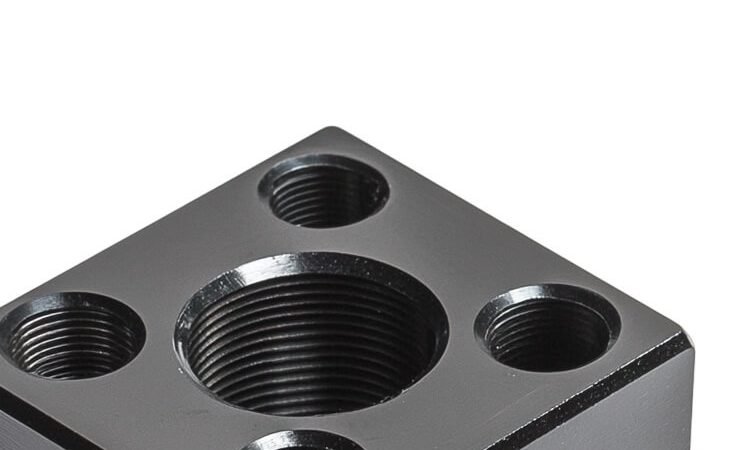

| Threads & Holes | For Φ 1.5-5 mm, depth is 3x diameter; For Φ 5 mm+, depth ranges from 4-6x diameter. |

| Wall Thickness | Minimum 0.8 mm for metals; 1.5 mm for plastics. Thicker walls boost stability. |

| Text Engraving | Minimum width 0.5 mm and depth 0.1 mm; engraving customizable to specifications. |

| Drilled Holes | Minimum 1 mm diameter; optimal depth is 4x diameter to maintain precision. |

| Pocket Depth | Limit depth to 4x tool diameter; deeper pockets require more machining time and care. |

| Design Complexity | Simplify geometries; complex features may increase cost and machining time. |

Various Industrial Applications

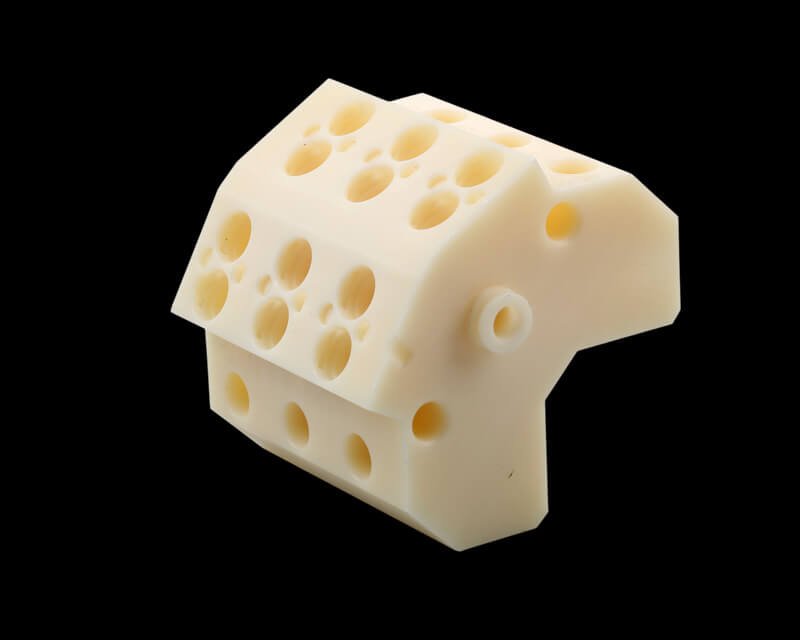

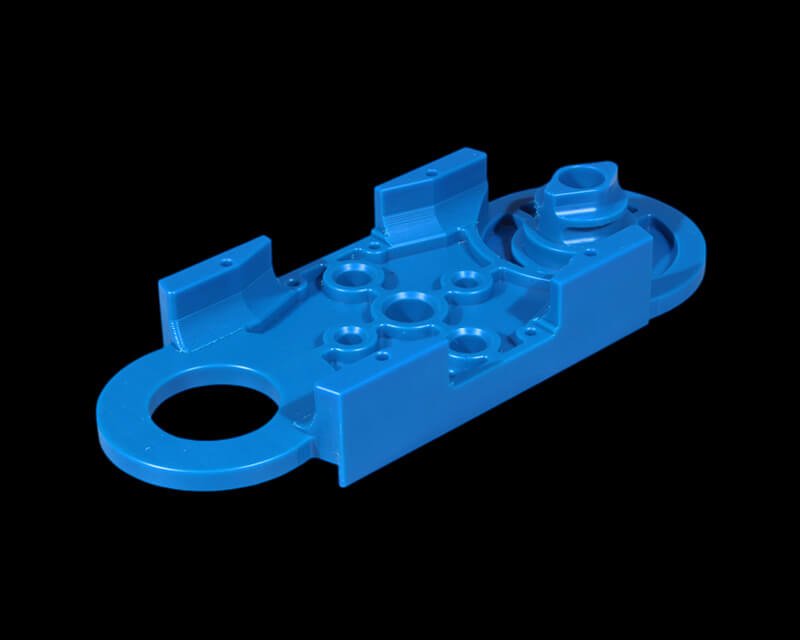

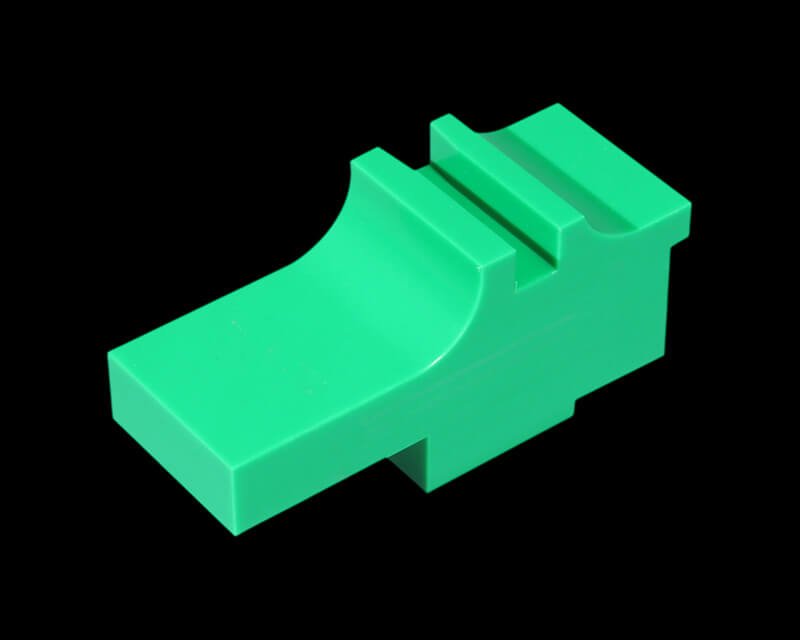

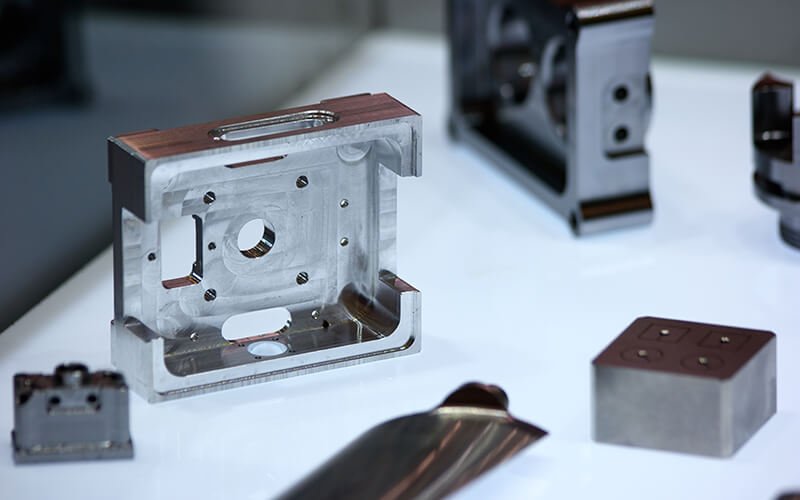

CNC Milling Parts Gallery

Why Choose Us

Choose us for precision, speed, reliability, and expert-driven manufacturing solutions.

Precision Quality

Fast Turnaround

Cost Efficiency

Technical Expertise

Flexible Capacity

Stable Supply

Instant & Accurate Quotes

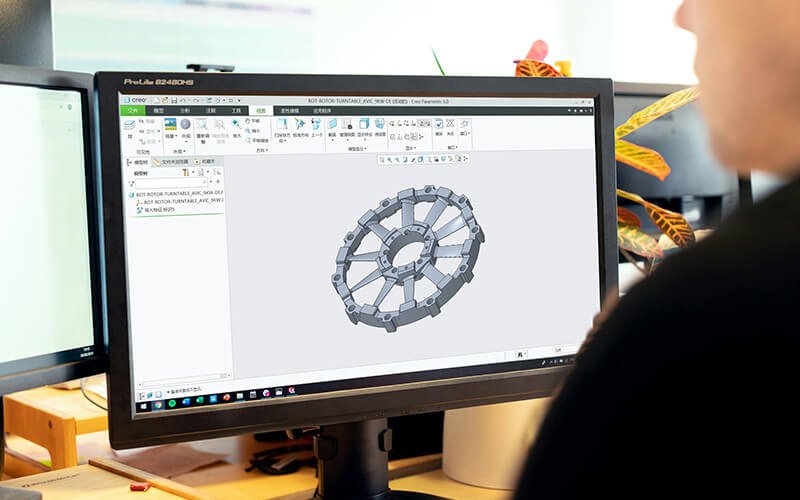

DirectProto's Advantage: Human Expertise in Quoting

Knowledge of CNC Milling

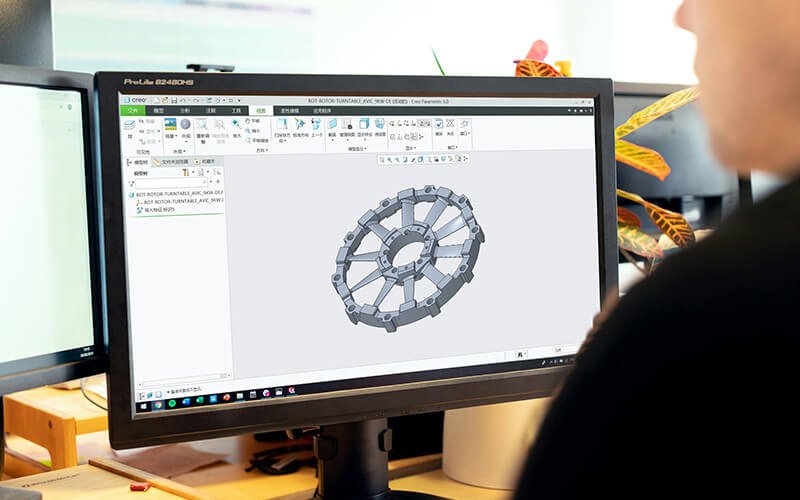

How Does CNC Milling Work?

Advantages of CNC Milling

Precision Mastery

CNC milling delivers unmatched accuracy, ensuring tight tolerances and consistency across complex designs and materials.

Efficiency Boost

Maximize production speed with automated processes, reducing lead times and increasing output without sacrificing quality.

Material Versatility

From metals to plastics, CNC milling adapts to diverse materials, accommodating various industry requirements.

Cost Effectiveness

Optimize resources by minimizing waste and reducing labor costs, contributing to competitive pricing and profitability.

Design Flexibility

Easily modify designs at any stage, allowing for rapid prototyping and seamless adjustments without additional tooling.

Scalability Assurance

Efficiently scale from prototypes to large batches, meeting demands across industries with reliable consistency.

Applications of CNC Milling

Precision Gears

Craft high-accuracy gears for automotive and industrial applications, ensuring seamless power transmission and durability.

Medical Devices

Produce intricate surgical instruments and implants, meeting stringent healthcare standards and enhancing patient care.

Robotics Parts

Create detailed robotic components, achieving superior precision and functionality for dynamic, automated systems.

Aviation Panels

Fabricate complex aerospace panels, optimizing weight and strength for safety and performance in high-flying conditions.

Custom Fixtures

Develop specialized tooling and fixtures, streamlining production workflows and improving machining efficiency.

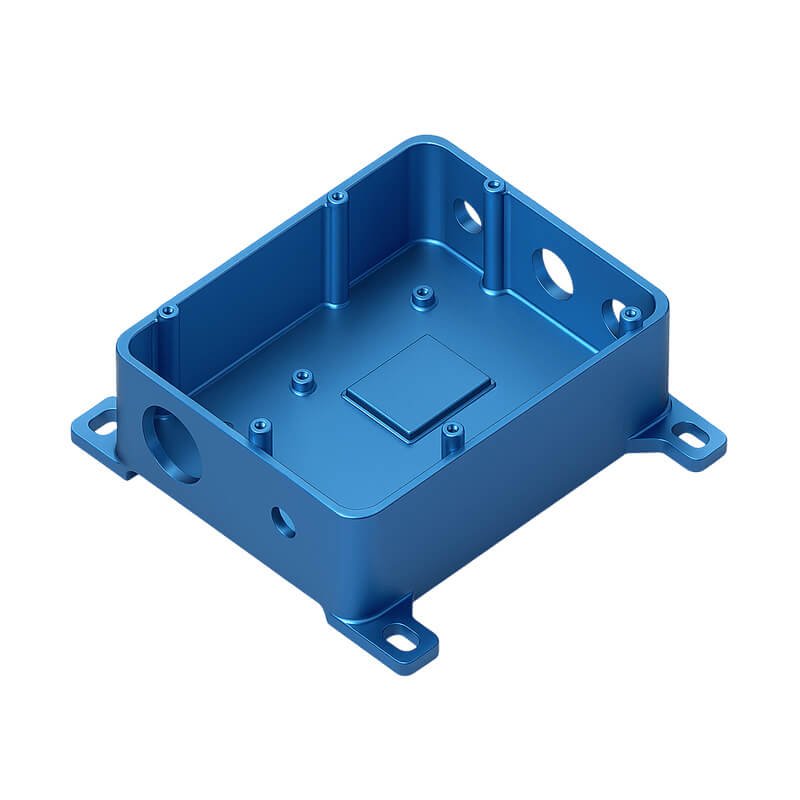

Electronic Housings

Design and mill protective housings for electronics, ensuring component safety and optimal performance in various environments.